Reflective Vinyl Overview - What Kind? What Rating?

Reflective vinyl is great, isn’t it? It can add a little pop to a graphic on your car, warn you of upcoming intersections or, if angled just right, flash you in the eyes while driving at night, making it impossible to see anything.

The technical term for the reflective effect is retroreflective. Normal surfaces scatter incoming light in all directions. A miniscule portion of light bounces off and returns to the light source. In the technical sense of the word, a reflective surface is a mirror. Incoming light bounces off at the same entrance angle. Retroreflective takes incoming light and returns it right back where it came from no matter the entrance angle. However, “retroreflective” is a hoity-toity scientific word. In everyday language, we skip the “retro” part of “retroreflective” and simply call the material “reflective vinyl.”

While reflective vinyls come in far fewer colours than their popular opaque vinyl cousins, there are quite a few options to choose from depending on the application.

Beaded vs Prismatic

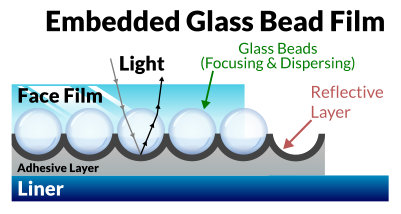

The two main varieties you will run into are beaded and prismatic reflectives. Beaded reflectives have tiny glass beads mixed into the pigment. These beads act as lenses, focusing and bending light. Light shines into the beads and bounces back out. This variety returns the most light when the source light is at a similar angle as your eye. Glass bead reflectives are typically more flexible and conformable than prismatic.

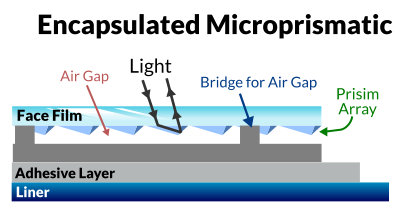

Prismatic, on the other hand, has tiny little pyramids embedded in the vinyl. Picture Pink Floyd’s album cover from The Dark Side of the Moon. The film has a patterned surface; diamonds, triangles, and fish scales being the most common. Prismatic reflectives reflect more light and remain reflective when the source light changes angles. Prismatic reflectives are trickier to manufacture than glass bead reflectives. Consequently they are more expensive.

ASTM Ratings

Now we get to the most confusing part. Because different types of reflectives will reflect light at greater or lesser angles and with greater or lesser brightness, a rating scale was developed to make sure the right reflectives are used for the right purposes. For general decals this won’t matter much. It is crucial for road signs, though, so check the requirements and then choose the appropriate vinyl. What you will see is a rating called ASTM D4956. The ratings break down into Roman numeral types ranging from Type I through Type XI. Type I is by far the most common. Greater reflectivity usually (but not always) corresponds to a higher Type number. Type I is the least reflective. Type XI is the most reflective. Don’t worry too much about descending the rabbit hole of angle/candle power/meter2 that defines each Type, just make sure that you are meeting the minimum requirement stated for the application (e.g., ASTM D4956 Type IV). You can shop our reflective products by ASTM Type or get an overview from our cross-reference chart for traffic reflectives.

Printing

Many reflective vinyls are printable, and our website indicates which ones are compatible with what type of inks. It is important to be aware though, that printing will reduce the level of reflectivity. Do a test print to see how much reflectivity will be reduced. It can prevent disappointed customers and expensive botched projects. For traffic signage, generic solvent printing will not maintain the ASTM D Type rating. Special certified printers are required.

Conformability and Cutting

A couple key details should be noted when working with reflective vinyls.

Due to materials used, reflective vinyls are not as flexible as ordinary cut vinyls. You will need to make sure that you are choosing the right one for the project. As an example, the Oralite 5400 series is really only good for flat application. Using it on a curved surface, even just a simple curve, may lead to lifting edges not long after application. The Oralite 5600, on the other hand, is much more conformable. It is designed to handle moderate curves and rivets.

Plotter cutting is another process you may find more difficult. Increased cutting force and a standard 45° blade may cut some reflectives, but it will dull the blade much faster. The better option is to use a 60° blade and double check that your cutter settings are adjusted for reflectives.

While you will need to check your machine for appropriate settings for reflective vinyls, most other details can be found on our website. So, whether you want to jazz up some decals, put some signs up around town, or need to outfit the local fire department with new reflective strips for their trucks, now you know what you will be looking for.

All comments