How To: Solvent Printing on Chrome Vinyl

Is it possible to print directly onto chrome vinyl with solvent or eco-solvent inks? The topic is a thorny one. Some people try and it works great. Other people try and it ends in disaster. We say it is possible. Absolutely possible. Learn about the film, avoid the biggest pitfall, and apply a few tricks. You’ll be part of the it-works-great group in no time.

Please note, this article focuses on solvent and eco-solvent inkjet systems. Although some of the problems and factors may carry over to UV curable and latex systems, the solution targets solvent and eco-solvent systems specifically.

Latex Update: See the end of the article for practical information about latex printing.

Bulletproof Printed Chrome

If you want inkjet printed chrome vinyl with a rock-solid production and performance guarantee, use this method. Print on clear vinyl or laminate. Top with a laminate if desired or required. Apply the printed film to chrome.

With this method, you can use any chrome vinyl - it doesn’t have to be printable. Yes, your customers will pay for two or three films. That’s the price of top performance. As always, match films of similar construction and durability. For example, Oracal 351 Chrome, Orajet 3651 Transparent, and Oraguard 210 Laminate.

The Issue of Direct Solvent Printing: Curling

Some chrome films are capable of direct inkjet printing. Express Sign Products offers three: Gemstone Chrome Polish, Universal Products UP-683 Premium Chrome Mirror, and RTape VinylEfx Smooth Silver. All three are metalized PVC films – a very different animal than metalized polyester films. However, none of these films print as effortlessly as your preferred go-to inkjet vinyl. All of them are sensitive.

By far the most common problem is edge curling. You print your graphics, you cut them out, and suddenly the vinyl is curling and lifting right off the liner. Sometimes the edges are lifting after installation. No one wants costly redoes or dissatisfied clients. A few considerations will tame the beast.

The Factors

Film construction is the primary factor. A metallized PCV film will consist of, at minimum, three layers: an adhesive, a metal film, and a PVC film. Everything hinges on the interaction between these three. If one material changes, the others must respond.

Temperature is the second factor. To explore this, lets dive down a rabbit hole and head back to high school physics class.

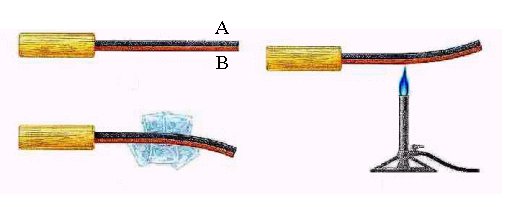

Remember anything about bimetallic strips, thermostats, or heat expansion? Look at the graphic. With a bimetallic strip, two dissimilar metal strips are bonded together. Each metal expands and contracts with temperature changes, but they expand and contract at different rates. When both metals are chilled, Metal B shrinks more than Metal A. The strip curls down. When both metals are heated, Metal B expands more than Metal A. The strip curls up. What does this have to do with chrome vinyl?

Chrome films contain a minimum of three materials. Each layer has its own heat expansion rate. As the different materials expand at different rates, guess what’s going to happen. Curling. Additionally, exposure to heat can permanently shrink PVC film. The metal film will cool and return to its previous size. The PVC? As it cools, it can shrink and end up smaller than it was. More curling. The effect is magnified if only part of the film is heated. If the whole roll or whole graphic is heated slowly and evenly, the curling effect will be minimal. If a very localized section of the roll or graphic is heated aggressively, the chrome vinyl will start tunneling and wrinkling on the release liner. To top everything off, intense heat can harm the adhesive. An adhesive with reduced effectiveness can’t combat any curling.

Ink density is the last factor. Solvent and eco-solvent inks interact chemically with the PVC causing it to shrink. Remember, if one layer changes, the other layers respond. The more ink used, the more the PVC changes. Also, the more ink used, the longer the interaction period. Hence, ink density greatly affects curling.

Mind you, this is a simplified explanation. There are additional, more complex factors and interactions at play.

The Solution

Unfortunately, there is no one thing you can do to magically eradicate edge curl. You can’t change the way chrome vinyl is constructed. However, there are many small factors that you can control. Combined, these factors create a solution to the problem.

Control the heat during printing. Choose a temperature setting between 35°C and 40°C. This will keep expansion and contraction to a minimum. It will also reduce the localized heating effect that can lead to tunneling.

Control ink saturation. Generally, a printing profile for intermediate calendered high gloss vinyl will provide a balance between vibrancy and curling. Since different printers have different settings and ink systems, test a lower-density profile if edge curl becomes an issue.

Control the duration of time allowed for outgassing. A minimum of 24 hours outgas time is recommended before cutting, laminating, or applying. Keep in mind. A normal printer heat setting kickstarts the ink curing process. Low heat means more time is needed for curing.

Control borders. Leave a ¼” wide unprinted border around all contour cut graphics and logos. Don’t cut into printed areas. These areas contain the greatest PVC shrinkage – essentially a tightly wound spring, waiting to be freed for action. An unprinted border resists the curling effect. It’s like cooties. Keep your distance and you won’t catch the dreaded curl.

Control lamination. If you are concerned about edge curling or if for some reason you cannot control other factors, consider applying a laminating film. The thickness and lay flat properties of a laminating film will calm any curling tendencies. The thicker the laminate, the stronger its “layflatness.” However, keep in mind that thicker laminates tend to be less durable.

The last part of the solution is edge sealing. You can only seal the edges of graphics if you are installing them. Prevent grime from clawing under the graphic and you’ve prevented edge curl and edge lift.

So, does it work? Can you use solvent and eco-solvent ink directly on chrome vinyl? Sure thing. You understand the material. You know its one weakness. Mostly importantly, you know how to control production for the best results. You're in.

Summary

● Bulletproof solvent printed chrome

○ Print on transparent

○ Apply to chrome vinyl

● The problem: curling

● The factors

○ Multi-layer film construction

○ Temperature - expansion and contraction

○ Ink density

● The solution

○ Reduce printer heat setting

○ Reduce ink saturation

○ Outgas, outgas, outgas; 24 hours, minimum

○ ¼” unprinted borders around all graphics

○ Laminate

○ Seal the edges after installation

Latex Printing

Some of our customers have successfully used latex printers on Gemstone Chrome Polish. It is not guaranteed, but it works. Unlike solvent ink, which chemically changes the film, latex ink sits on top and leaves the film undisturbed. Ink saturation is not an issue. However, heat is still a problem.

● Latex recommendations

○ Test print

○ Feed vinyl past the heater to avoid curling and head strikes

○ Leave ¼” unprinted borders around all graphics

○ Cool film completely before contour cutting

○ Laminate for UV protection if needed

All comments